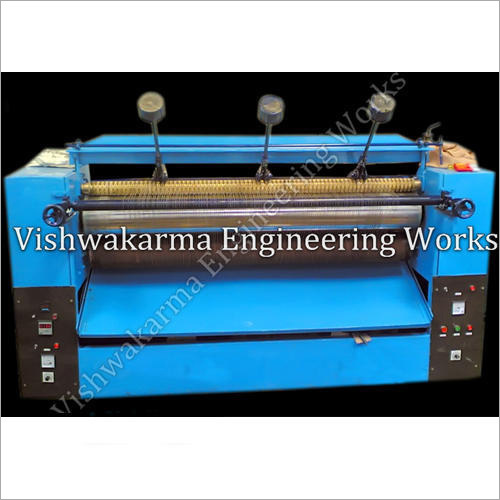

Product Description

Hazaro Plating Machine

Product details

|

A C Motor

|

2.H.P Single Face

|

|

Gear Box

|

2.N.U & 3N.U. with 40/1 ratio

|

|

Hitter

|

6 Pies

|

|

Machine length

|

2350 mm

|

|

Machine width

|

800 mm

|

|

Power

|

1.5 kW

|

|

Production

|

4000 Metter /24 house

|

|

Receive

|

30.1

|

|

Work height

|

1550 mm

|

|

Working Speed

|

0 to 100 RPM

|

Durable and Reliable PerformanceBuilt with a rigid frame and durable materials, the Hazaro Plating Machine provides long-lasting reliability for continuous industrial usage. Its automatic lubrication and integrated cooling system contribute to minimal maintenance and consistent plating results, ensuring high standards for manufacturing environments.

User-Friendly Controls & ConnectivityStandard wired controls make the Hazaro Plating Machine straightforward to operate, even for users with minimal training. The intuitive interface allows for fast adjustments, supporting efficient workflows and reducing downtime in busy production settings.

Perfect for Metal Plating ApplicationsDesigned specifically for industrial metal plating, the machine achieves uniform surface treatment through electroplating. Its stable voltage and frequency settings ensure optimized results for various types of metals, making it suitable for a range of industrial sectors across India and beyond.

FAQs of Hazaro Plating Machine:

Q: How does the Hazaro Plating Machine operate in terms of power and temperature?

A: The machine functions on a single-phase electric supply with a voltage range of 220V-240V and a power rating of 2.5 kW. It operates optimally at ambient temperatures between 20C and 40C, ensuring safe and efficient plating processes.

Q: What type of connectivity options does this plating machine offer?

A: Hazaro Plating Machine is equipped with standard wired controls for secure and seamless operation, providing stable communication between the control interface and machine components.

Q: Where can the Hazaro Plating Machine be used?

A: This machine is ideal for industrial settings that require metal plating, such as manufacturing plants, automotive component production facilities, and hardware fabrication units. It is supplied by reputable exporters and manufacturers in India.

Q: What is the benefit of the automatic lubricating system?

A: The automatic lubricating system reduces manual intervention, ensures proper functioning of moving parts, and prolongs the lifespan of the machine through consistent maintenance.

Q: When should the machines integrated cooling system be used?

A: The integrated cooling system functions continuously during operation, maintaining optimal temperatures during the plating process to prevent overheating and to guarantee stable performance.

Q: What surface treatments are supported by the Hazaro Plating Machine?

A: The machine is designed for electroplating applications, providing a uniform and durable metal finish suited to diverse industrial requirements.