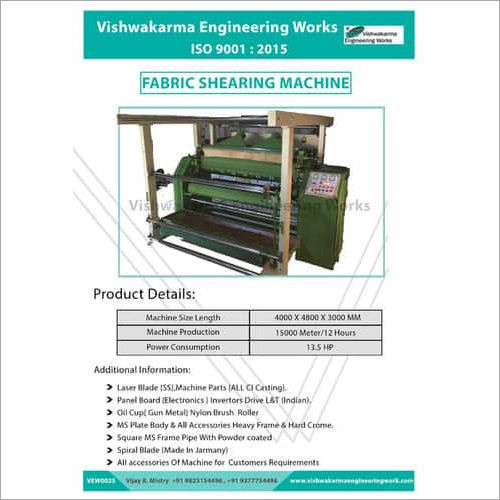

Product Description

Fabric Shearing Machine (Saree Weft Cutting Machine )-Our competency lays in manufacturing and supplying our clients an excellent quality range of Fabric Shearing Machine. The offered machine is widely demanded in textile industries for designing fabric in different patterns and color combination. Our offered machine is manufactured with the help of abrasion resistance material and cutting-edge technology under the visionary guidance of skilled professionals. We offer this machine in different technical specifications for our clients with different choices.So that the actual price of machine can be vary at the time of placing the order due to present market condition and customers requirement.

Product details

|

Voltage

|

250-380V

|

|

Weight

|

1.5-2 Ton

|

|

Motor Power

|

5-7.5 Hp

|

|

Hold-down Force

|

Spiral & Ledger Blade

|

|

Condition

|

New

|

|

Operation Mode

|

Automatic

|

|

Max Shear Width

|

2000-3000 mm,1000-2000 mm,500-1000 mm,0-500 mm

|

|

Cutting Material

|

All Fabrics

|

Precision Cutting with Versatile SizingThe Dhaga Cutting Shearing Machine is engineered to deliver high-precision cuts on yarns and threads of all thicknesses. Its advanced mechanism allows seamless adjustment, supporting any cutting size starting from 0mm. With automatic features and an intuitive Human Machine Interface, operators can efficiently manage batch production with consistent results, making it essential for textile manufacturers seeking accuracy and scalability.

Robust Construction and Reliable PerformanceBuilt with longevity in mind, this machine features a durable steel frame measuring 4000mm x 4800mm x 3000mm. Equipped with German-made spiral and ledger blades, it withstands rigorous use while maintaining top cutting standards. Designed for heavy-duty operations, its weight, ranging between 1 and 1.5 tons, ensures stability and smooth functionality. Backed by a 1-year warranty, it offers manufacturers peace of mind and reliable support.

FAQs of Dhaga Cutting Shearing Machine:

Q: How does the Human Machine Interface enhance the operation of the Dhaga Cutting Shearing Machine?

A: The Human Machine Interface (HMI) simplifies machine interactions, allowing operators to easily set parameters, monitor production status, and perform diagnostics. This user-friendly control panel streamlines setup, reduces downtime, and improves overall efficiency during operation.

Q: What types of materials can the Dhaga Cutting Shearing Machine handle, and what are its cutting size capabilities?

A: The machine is designed for cutting yarns and threads of varying thicknesses. It accommodates all cutting sizes, beginning at 0mm, enabling versatile applications across different textile production requirements.

Q: When is the best time to schedule routine maintenance for this shearing machine?

A: It is recommended to perform routine maintenance every 3 to 6 months, depending on usage intensity, to ensure optimal blade sharpness and machine reliability. Always refer to the manufacturers maintenance guidelines for best results.

Q: Where is the Dhaga Cutting Shearing Machine manufactured and supplied?

A: This shearing machine is manufactured in India and is available for export, as well as domestic supply, making it accessible for textile producers nationwide and internationally.

Q: What is the process for using and adjusting cutting sizes on this machine?

A: Operators use the HMI control system to adjust settings according to the required cutting size. The process is automatic, and the machine supports all sizes from 0mm upward, allowing for straightforward batch adjustments without manual reconfiguration.

Q: What are the benefits of choosing this machine for textile manufacturing?

A: Key benefits include reliable and precise automatic cutting, compatibility with all sizes, robust German blade quality, intuitive controls, and an industry-standard 1-year warranty for comprehensive support, boosting productivity and consistent output.